Technical Principle

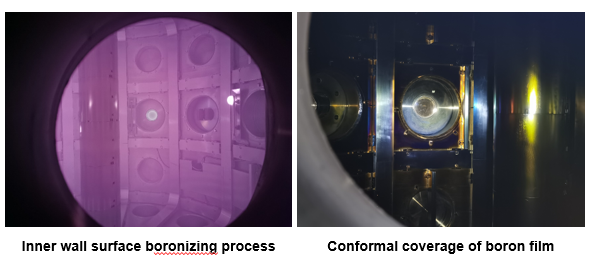

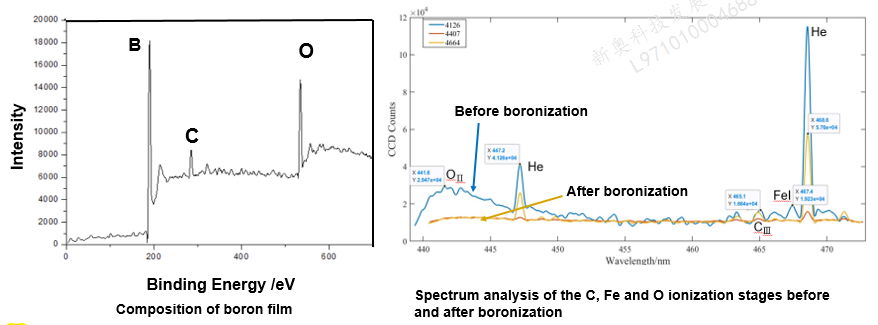

In fusion technology, the deposition of a thin boron film conformally coating on the inner wall of the vacuum chamber plays an important role in effectively preventing metal impurities, oxygen and carbon elements from moving into the central hot plasma. The boron deposition is prepared by the plasma-enhanced chemical vapor deposition (PECVD) method with borane such as B2H6 and B10H14 or organic boride such as B(CH3)3 and C2B10H12 as the boron source.

Significance

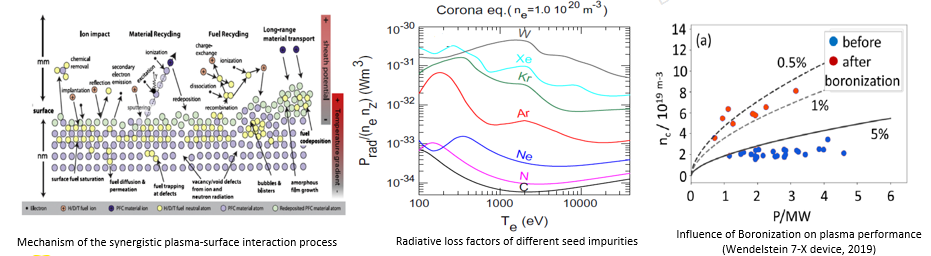

In the fusion chamber, the extremely hot plasma inevitably interacts with the inner wall so that all kinds of impurities and gases in the wall will be gradually released and enter into the central plasma, leading to an enormous loss of the plasma energy and. The in-situ growth of boron film conformally coating on the inner wall of the fusion chamber is able to effectively prevent the leakage of the metal impurities, oxygen and carbon elements, thus to remarkably reduce the loss of plasma energy and greatly improve plasma performance .

Technology Status

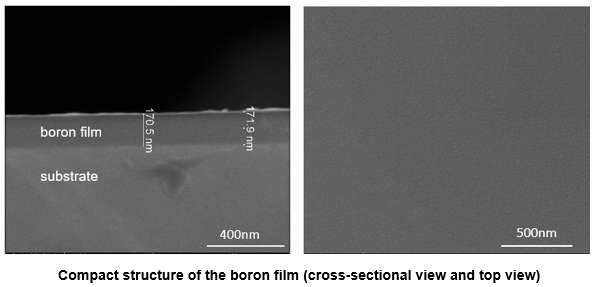

Wide thickness range of 10-300 nm;

Controllable deposition rate of 0.6-5 nm/min;

Strong adhesion with the substrate of more than 240 N/m.