Technical Principle

Plasma is a hot, conductive, ionized gas that is produced by contact with a strong electric arc. The gas is broken down into negatively charged electrons and positively charged ions, making its electrical and thermal conductivity greatly enhanced. An arc plasma generator, also known as a plasma torch, is an electrical discharge device capable of producing a directed low-temperature (~2000-20000K) plasma jet.

Significance

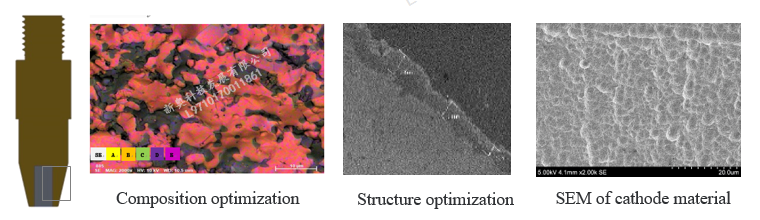

The cathode plays the most important role in the plasma torch and is gradually ablated by the bombardment of the heavy and extremely hot positive ions. Through well design of material composition with addition of rare metal elements as well as advanced preparation technology controlling grain sizes, the capability of electron emission could be remarkably improved with increased ablative resistance and enhanced arc starting stability, thereby increasing the whole life time of the plasma torch.

Advantages

1. extremely long service life time of more than 100 hours in the water vapor;

2. large current density with high stability;

3. hundreds of kW power of emitted plasma;

4. wide adaptability to various working medium including the inert, oxidative and reductive ones.

Application

The plasma torch is used in a wide range of industrial application, including cutting, thermal spraying, welding, smelting, new material synthesis, ultrafine powder preparation, wastewater treatment and others, due to its extremely high-temperature heat source, highly focused energy concentration and high heating efficiency. In the plasma torch industry, the cathode material is the key consumables with increasingly vigorous demand. Meanwhile, the developed cathode material may also find its promising application in the development of vacuum electronic devices, which will open up new business market.

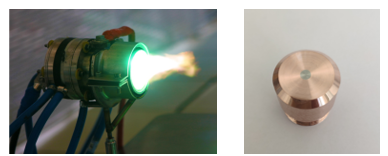

Plasma torch Cathode in the base