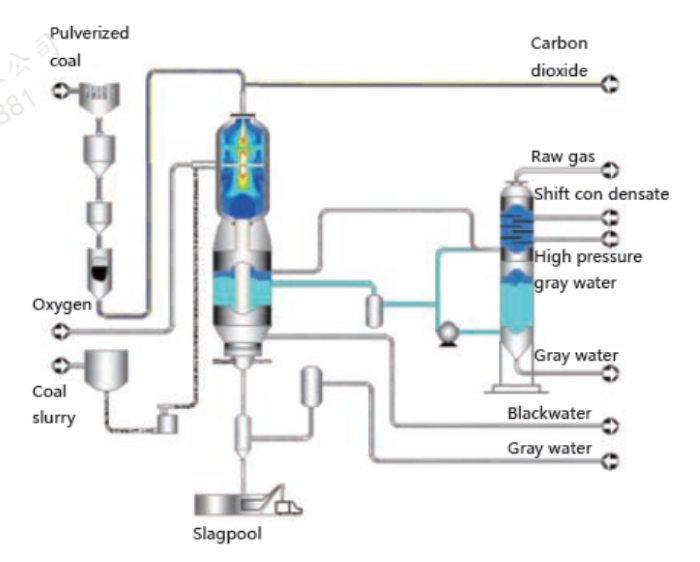

ENN developed pulverized-coal and slurry gasification technology by integrating the mature technologies of coal-water-slurry (CWS) gasification and high pressure dense-phase pneumatic conveying of pulverized coal. In comparison with conventional CWS gasification, the novel process reduces oxygen and coal consumption with increased cold gas efficiency and gas output. The joint gasification process is adaptable to a wider range of coals, offering a promising solution for the clean coal future.

Technical Principles

ENN pulverized-coal and slurry gasification is a process in which the pulverized coal and CWS are simultaneously injected into the gasifier to improve the coal concentration. By adjusting the proportion of CWS and pulverized coal and the feeding angle, the gas-solid flow pattern and reaction performance in the gasifier can be optimized, achieving efficient co-gasification of the feedstock.

Competitive Advantages

Fuel Adaptability: By adjusting the proportion of pulverized coal and slurry, low rank coal like lignite and coal with poor slurryability can be used as feedstock. Thus, the raw material cost can be reduced via flexible coal blending strategy.

Gasification Performance: When the input of dry pulverized coal is up to 1/3, the coal concentration in the slurry can reach 68%. The effective gas composition and cold gas efficiency are improved by 4 to 6%, while the oxygen consumption decreases by 15% and coal consumption by 11% than conventional coal slurry gasification.

Environmental Impact: When applied to methanol production, the overall energy consumption is 1.6 tce/ton methanol (lower than the national advanced standards). Meanwhile, partial carbon dioxide is recycled as conveying pulverized coal, resulting in a 10% cut of CO2 emissions during methanol production.

Technology Status

Over the past three years, ENN has developed intellectual property rights in pulverized-coal and slurry gasifier, multi-channel burners, high pressure dense phase conveying of pulverized-coal using CO2 and pulverized-coal and slurry gasification control technology. As of December 2019, the research team has filed over forty patent applications for the technology.

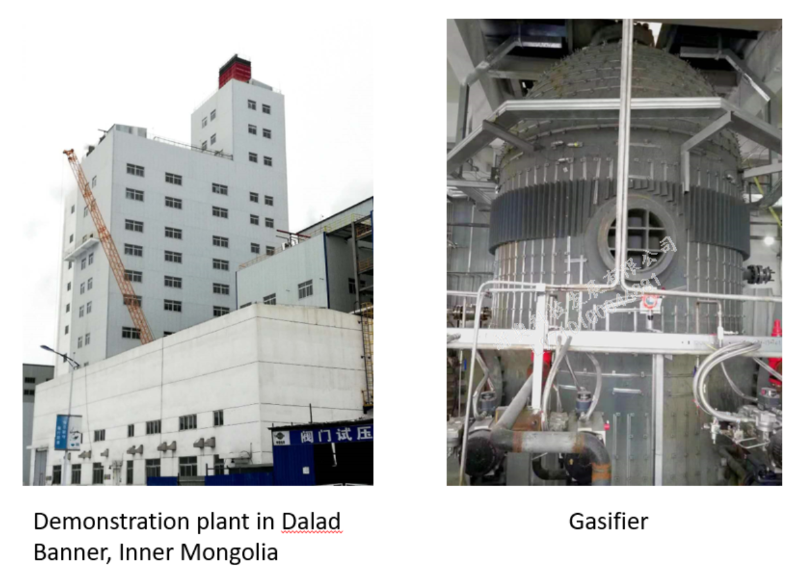

In 2017, ENN commenced construction of its demonstration plant with a total processing capacity of 1,500 tons per day in Dalad Banner, Inner Mongolia and commissioning is scheduled for 2020.